Armored, Single Jacket PE/LSZH (Anti-rodent)

- Description

- . Fiber Optic Cable

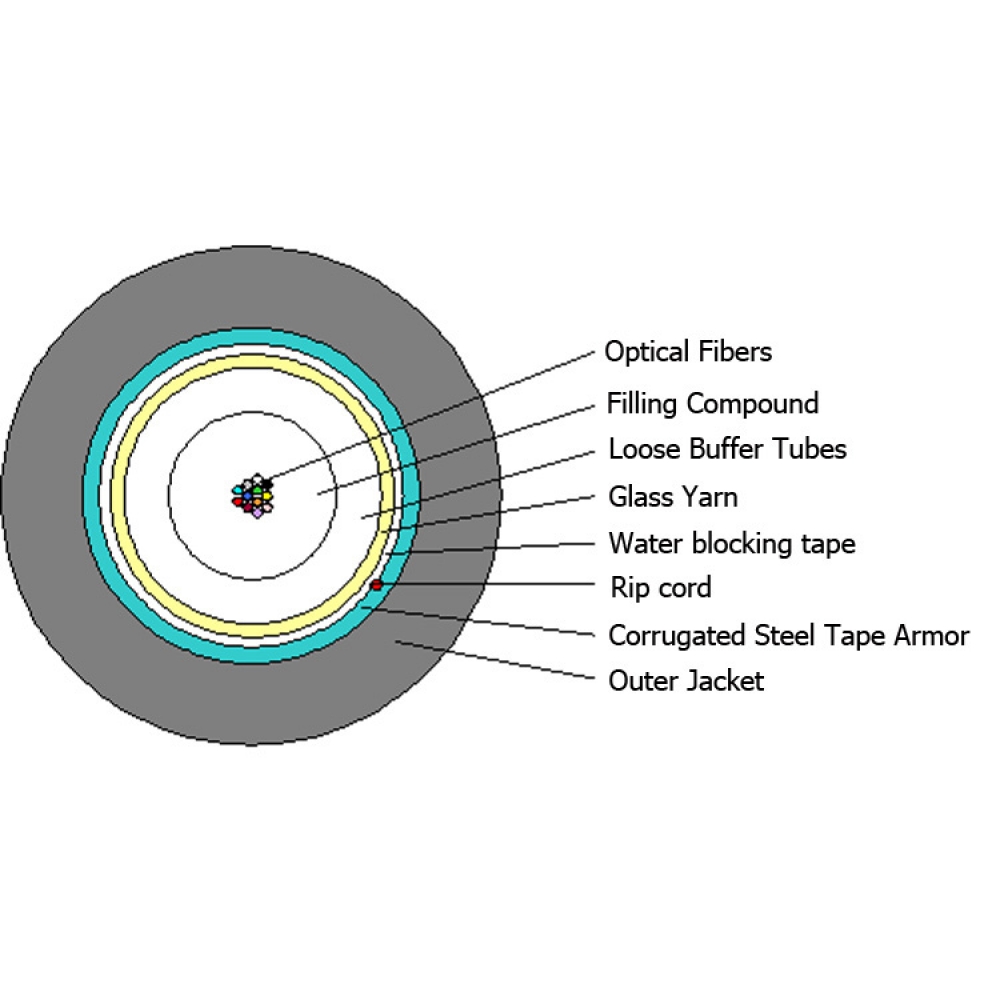

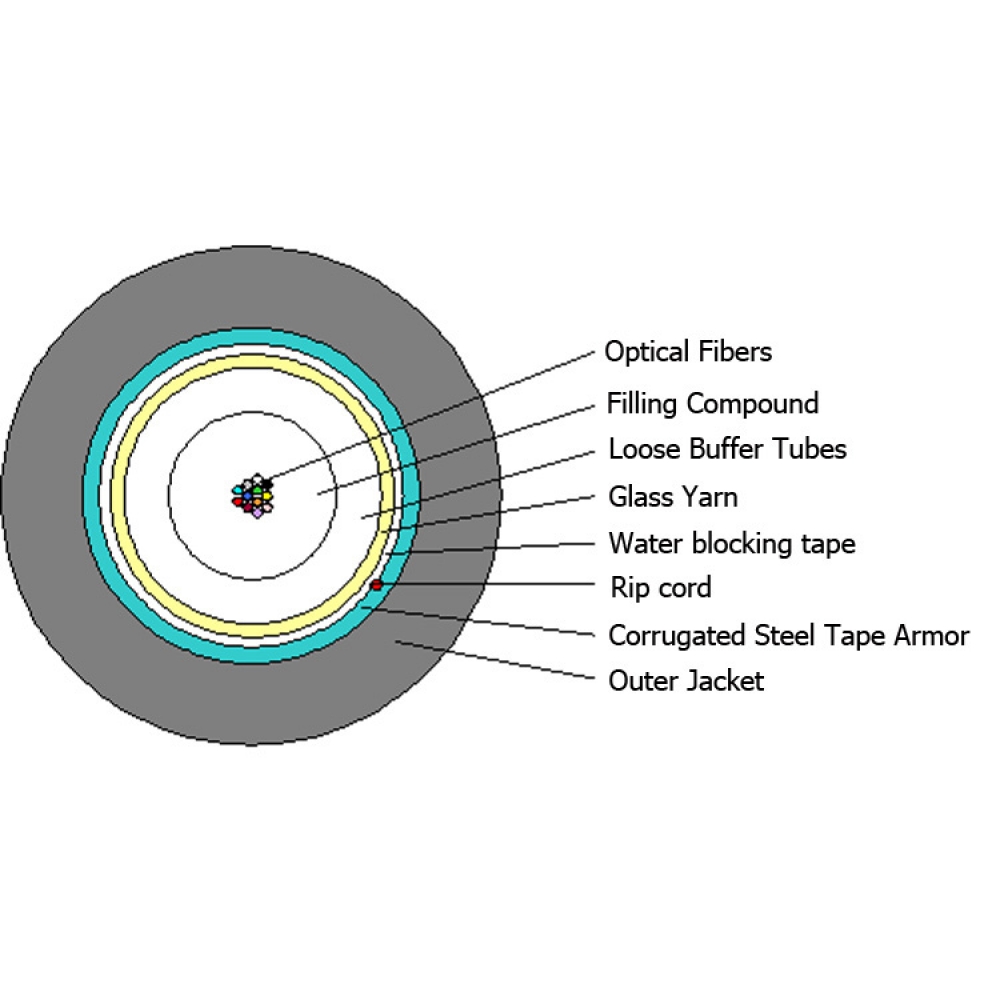

. Central Loose Tube / Armored / Single-Jacket PE or LSZH (Anti-rodent)

. Color coded fibers, gel filled central loose tube, glass yarns, strength member, water blocking tape, corrugated steel tape armor and outer PE or LSZH jacket

- Cable Construction

ITEMS DESCRIPTION Number of Fibers Max. 24 Loose Buffer Tube PBT (Polybutylene Terephthalate) Filling Compound

in Loose Buffer TubeThixotropic Jelly Compound Strength Member Glass yarns Water Blocking tape Water blocking tape Ripcord One ripcord Armor Material Corrugated Steel Tape with Plastic Coating Thickness Nom. 0.15mm (Steel Tape)

Nom. 0.05mm (Plastic Coating on both sides)Outer Jacket Material Black HDPE or LSZH Thickness Nom. 1.5 mm (HDPE) / Nom. 1.8mm(LSZH)

- Mechanical and Environmental Performance

ITEMS TEST METHOD AND

ACCEPTANCE CRITERIATensile Strength # Test method: IEC 60794-1-2 Method E1

-. Mandrel diameter: 30D (D = cable diameter)

-. Installation tensile load: 1,250N for 1 hour

# Acceptance Criteria

-. Attenuation increment: ≤ 0.10 dB/km (SM)

≤ 0.20 dB/km (MMF)

for residual tensile loadCrush resistance # Test method: IEC 60794-1-2 Method E3

-. Load: 2200 N/10cm for 10 minute

# Acceptance Criteria

-. Attenuation increment: ≤ 0.10 dB/km (SM)

≤ 0.20 dB/km (MMF)

after completion of the test

-. No jacket cracking and fiber breakageImpact resistance # Test method: IEC 60794-1-2 Method E4

-. Impact energy: 10 N.m

-. No. of impact per point: 1 time at 3 points each

# Acceptance Criteria

-. Attenuation increment: ≤ 0.10 dB/km (SM)

≤ 0.20 dB/km (MMF)

after completion of the test

-. No jacket cracking and fiber breakageRepeated Bending Test # Test method: IEC 60794-1-2 Method E6

-. Mandrel diameter: 20D (D = cable diameter)

-. Load : 10kg

-. No. of cycles: 35 cycles

# Acceptance Criteria

-. Attenuation increment: ≤ 0.10 dB/km (SM)

≤ 0.20 dB/km (MMF)

after completion of the testTorsion Test # Test method: IEC 60794-1-2 Method E7

-. Cable length twisted: 2m

-. No. of twist cycles: 5 cycles

-. Twist angle: ± 180°

# Acceptance Criteria

-. Attenuation increment: ≤ 0.10 dB/km (SM)

≤ 0.20 dB/km (MMF)

after completion of the testTemperature Cycling Test # Test method: IEC 60794-1-2 Method F1

-. Cable length: at least 500m

-. At least 6 fibers shall be spliced and tested.

-. Temperature cycling schedule

: 23°C → -20°C → 70°C

-. Soak time at each temperature: 12 hours

-. No of cycles: 2

# Acceptance Criteria

-. Attenuation increment: ≤ 0.15 dB/km (SM)

≤ 0.30 dB/km (MMF)Water Penetration Test # Test method: IEC 60794-1-2 Method F5

-. Length of specimen: 3m

-. Height of pressure head: 1m

-. Test time: 24 hours

# Acceptance Criteria

-. No leakage through the open cable endFlammability Test

(LSZH Jacket Cable only)# Test method and Acceptance Criteria

The cable shall comply with IEC 332-1.

- Application

- Fiber optic telecommunication cables used for duct and direct burial application